Rebuilt engines are a great way to save money and reduce the risk of buying a used engine. These engines while more costly than used, will perform better and longer. A rebuild also costs about 50% less than a new crate motor. In this article I will share where to find rebuilt engines near me, Frequently asked questions, the pros and cons, and the alternatives.

Map of Rebuilt Engines Near Me

For “Rebuilt Engines Near Me” see the map below…

Who Rebuilds Engines Near Me

There are various types of companies that do rebuilds. There are mechanic shops, industrial machine service shops, engine shops, commercial fleet management companies, equipment manufacturers, and even some salvage yards.

The three biggest industry names in the rebuilding business and the remanufacturing process of engines are:

You can find a variety of places that either sell rebuilt engines or will rebuild an engine for you. Many folks have the motor already but don’t have the time, technical expertise, or equipment to assemble their own engine.

What is a Rebuilt Engine?

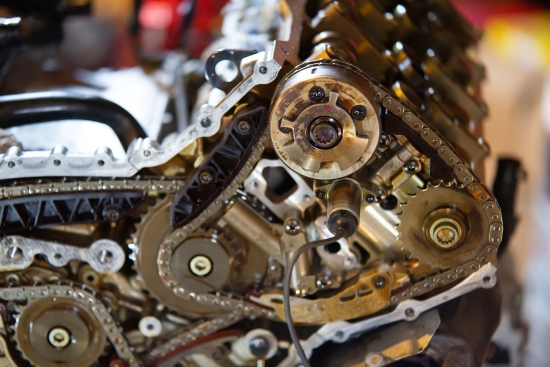

Rebuilding an engine is the process of taking a part of a used motor and then only replacing parts that are damaged or worn out. Any parts that are currently functioning remain in their current state. This process extends the life of an engine and makes greater use of serviceable parts rather than replacing all components with new parts.

It’s important to distinguish the difference between rebuilt and remanufactured engines. A remanufactured engine is a complete overhaul of an engine (except the body) to restore the engine to “like new”. It is benchmarked against the OEM factory tolerances and certified as remanufactured.

What Kind of Engines Get Rebuilt?

There are various types domestic engines that get rebuilt. Here are the most common rebuilt engines near me:

- Heavy-duty diesel engines

- Automotive gasoline engines

- Heavy-duty gasoline engines

- Automotive diesel engines

What to Expect When You Drop Off an Engine…

All businesses of course run differently and have their own processes. Generically speaking from my experience with the places who rebuild engines near me right engine, here is how the process goes:

- Drop Off: You deliver your engine and sign some paperwork.

- Disassembly: They break your engine down into bare bones. The assemblies and parts are cleaned and inspected. Parts are then labeled for either functioning needs matching, or needs replacement.

- Quote: They contact you with a price quote that includes labor, replacement parts, machining, modifications, refinishing, coatings, and any other needed repair work. Also, they will provide a turnaround time estimate.

- Deposit: If you approve the quote, most places require 50% up front.

- Order Parts: Once they have your deposit they can order or source the needed parts.

- Machining/Refinishing: Parts are machined, bored, and modified to exact tolerances (check with your rebuilder as this is part of remanufacturing).

- Reassembly: The engine and all the components are reassembled.

- Shipped: The engine will be shipped back.

In my experience, they do not do any tuning. Once you get the engine back you have to tune it to your needs and specifications.

Do Rebuilt Engines Come with a Warranty?

This will depend on where you purchase the engine or you hire for the rebuild. Some rebuilds purchased as assemblies are only covered by a manufacturer or 90-day warranty. A shop warranty on rebuilt engines is usually around 3 years or 36K miles whichever occurs first and provided service is kept up. I have seen a few shops that will guarantee their rebuild up to 100K miles.

Pros and Cons of Rebuilt Engines

With a rebuild, there are both pros and cons:

Pros

- Cost-effective when compared to the price of a new motor.

- Cost-effective when compared to the price of a remanufactured motor.

- More dependable and reliable than a used engine.

- Often backed by warranty programs.

- Can improve gas mileage.

- Will emit fewer pollutants.

- Saves energy related to processing salvaged engines and vehicles.

- Assembly replacement engines have a low rate of error.

Cons

- More costly than a used engine.

- Less reliable then a remanufactured engine.

- Parts that were functioning and left as is during the rebuild, may need to be replaced at a future date which the owner is responsible for the cost of the service and rebuild.

- It’s not plugin and play: Parts and systems from the existing vehicle need to be integrated which can introduce new problems.

- The quality of a shop rebuild is directly reliant on the knowledge of a mechanic. Mechanics unfamiliar with the engine, may not know how to properly fix or troubleshoot.

- After-market auto parts often don’t meet the same quality standards as the OEM parts and may wear out faster.

- The owner is responsible for the cost of the service and rebuild, even if the engine has problems down the road.

- The average labor cost runs between $80 to $100 per hour for the tear-down and then rebuild, but replacement parts will cost additional.

Alternatives to Finding Rebuilt Engines Near Me

There are 3 alternatives to a rebuilt engine: new, used and remanufactured.

A new crate engine is obviously going to run you $2000+ depending on what kind of car and engine you are replacing. If it is a heavy-duty truck you will replace you can double that cost at least. The upside of course is you get a manufacturer’s warranty and the reliability of a brand new motor.

A used engine from a salvage yard or other source is going be your most affordable option, but comes with reliability risks. It is possible to find an almost brand-new engine at a salvage, but it’s easier said than done. Warranties on used engines are commonly 30 days and no cash back. The trouble with a used engine is the reliability questions: How did the previous owner treat it? Was the service kept up? How close is it to its end of life? How long is it going to last? There are certainly more benefits to chosing a rebuild over used.

A remanufactured engine is going to cost more than a rebuild, but less then new. A remanufactured engine is a complete teardown and overhaul of the engine. It will be made “like” new and built to meet the original factory tolerances. These engines are more reliable and there are cases where they actually out perform a new engine. They typically come with really nice warranties as well often in the 100K mile range.

For more info on used vs rebuilt vs remanufactured, read here.

Can You Rebuild an Engine Yourself

Yes, but rebuilding an engine on your own is an arduous task. However, with some upfront planning and research, you can reduce the chances of making a costly mistake. Between articles and YouTube you can learn to do the basics of:

- Removing and reinstalling the engine block.

- Disassembling and inspecting each of the components.

- Customizing your build to optimize the performance.

- Keeping costs controlled, by ordering your own replacement parts.

Read more about how to do an engine rebuild yourself, here. Also, check out 7 Mistakes to Avoid When Doing an Engine Rebuild.

Debunking Common Myths About Rebuilt Engines

- Myth 1 (Rebuilt Engines Are Less Reliable): One of the most prevalent myths about rebuilt engines is that they are less reliable than new ones. However, this is not necessarily true. When an engine is rebuilt, worn parts are replaced, and the engine is restored to meet OEM specs. This means that a remanufactured engine can be just as reliable as a new one, especially when brand new OEM parts are used in the rebuilding process.

- Myth 2 (Rebuilt Means Lower Quality): Many people believe that a rebuilt engine means a compromise in quality. In reality, engine remanufacturers often use the same or even better quality parts than those used in original engines. Damaged parts replaced during the rebuild process ensure that the engine runs smoothly. Moreover, many rebuilt engines come with a labor unlimited mileage warranty, which speaks to the confidence of the rebuilders in their work.

- Myth 3 (Rebuilt Engines Don’t Last Long): Another common misconception is that rebuilt engines have a shorter lifespan. The truth is, the lifespan of a rebuilt engine can be comparable to that of a new engine, especially when the rebuilding process includes re machined parts and strict adherence to OEM specs. The key is in the quality of the rebuild and the replacement of all internal parts that are worn or damaged.

Realities of Using Rebuilt Engines

- Reality 1 (Cost-Effective Solution): Choosing a rebuilt engine is often a smart choice for those looking to save money without sacrificing performance. Compared to purchasing a new or used vehicle, or opting for a new engine, rebuilt engines offer a cost-effective solution. They are typically priced lower than new engines, and the competitor price often reflects this.

- Reality 2 (Environmentally Friendly): Opting for a rebuilt engine is a more environmentally friendly choice. It reduces waste as it involves recycling parts and requires less energy and raw materials compared to manufacturing a completely new engine. This aspect of rebuilding engines contributes positively to the auto industry’s sustainability efforts.

- Reality 3 (Customization and Upgrades): When an engine is rebuilt, there is an opportunity for customization and upgrades. Engine remanufacturers can reverse engineer parts to improve performance or upgrade certain components to the customer’s preference. This flexibility is not often found with off-the-shelf new engines.

In conclusion, the decision to choose a rebuilt engine should be based on accurate information and an understanding of the benefits it offers customers. It’s a quality, cost-effective, and environmentally friendly option that can meet, if not exceed, the performance of a new engine.

Future Trends in Engine Rebuilding

Technological Advancements in Engine Rebuilding

The landscape of engine rebuilding is rapidly evolving, thanks to significant technological advancements. In the realm of engine swaps, mechanics are now able to integrate more sophisticated engines into a variety of vehicle models, enhancing performance and efficiency. This trend is not just about replacing old engines but about upgrading to more advanced ones.

Crate engines have also seen a surge in popularity. These ready-to-install engines are a testament to the convenience and reliability that modern technology offers. They come as a complete package, often including bearings, pistons, and gaskets, ensuring that all parts work seamlessly together. This is a stark contrast to the past when rebuilding an engine often meant sourcing each identical part separately.

Predictions for the Future of the Industry

Looking ahead, the industry is set to embrace more eco-friendly practices. The focus will likely shift towards remanufactured engines that meet Original Equipment Manufacturer (OEM) standards. This approach not only reduces waste but also ensures that the rebuilt engines are as good as new.

The use of advanced search tools and online platforms will make finding the perfect engine easier for customers. These tools will offer options like commercial address delivery, liftgate service, and flat rate shipping. Moreover, the convenience of residential delivery will further enhance customer satisfaction.

In terms of sales and services, we might see more transparent practices. Customers will have clearer insights into what they pay for, with detailed accounts of the rebuilding process. The option for a refund or return if the product doesn’t meet expectations will become standard, fostering trust and connection between rebuilders and their clients.

In conclusion, the future of engine rebuilding is not just about the engines themselves but about the entire ecosystem – from transmissions to customer service. The industry is moving towards a more customer-centric, environmentally responsible, and technologically advanced future.

Rebuilt Engines Near Me – Conclusion

Rebuilt engines are a great option for fleet management, reducing the costs of repairs, and auto restorations, and extending engine life. There are however many things to consider before you decide on going used, rebuilt, or remanufactured.

I think the key things to consider are whether you are getting an assembly or shop rebuild, the warranty, and whether or not you can do the work yourself. This is what I have learned from the places who rebuild engines near me.